Innovation Management

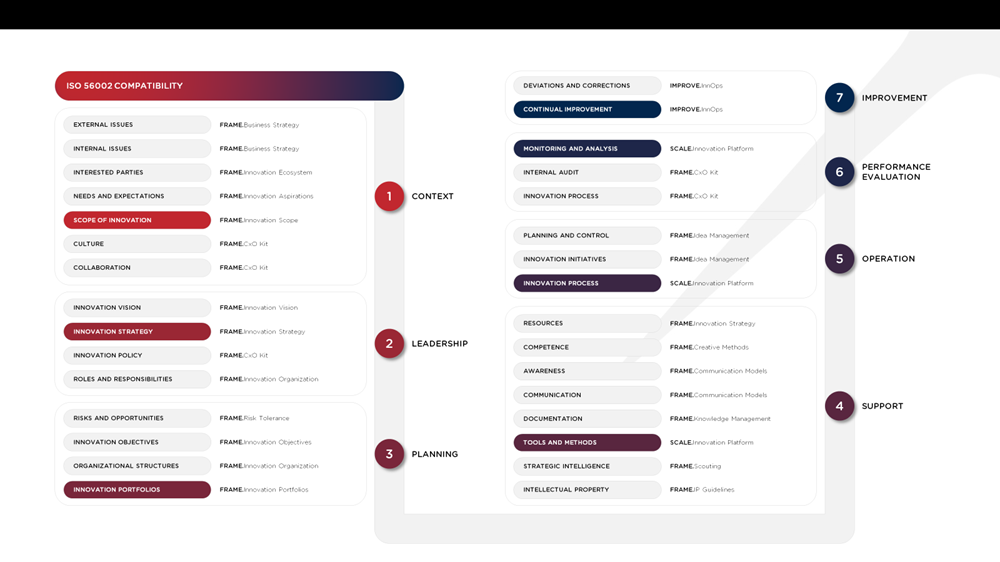

We structure and optimize your innovation engine, aligning processes with strategy for greater efficiency and customer appeal. Our comprehensive approach ensures your innovation activities produce measurable results aligned with business objectives.

Key Capabilities:

- Strategic innovation alignment

- Innovation portfolio management

- Cross-functional collaboration frameworks

- Innovation metrics and measurement

- Knowledge management systems

- Organizational innovation culture